From Ideation.

The process of creation always starts with an idea.

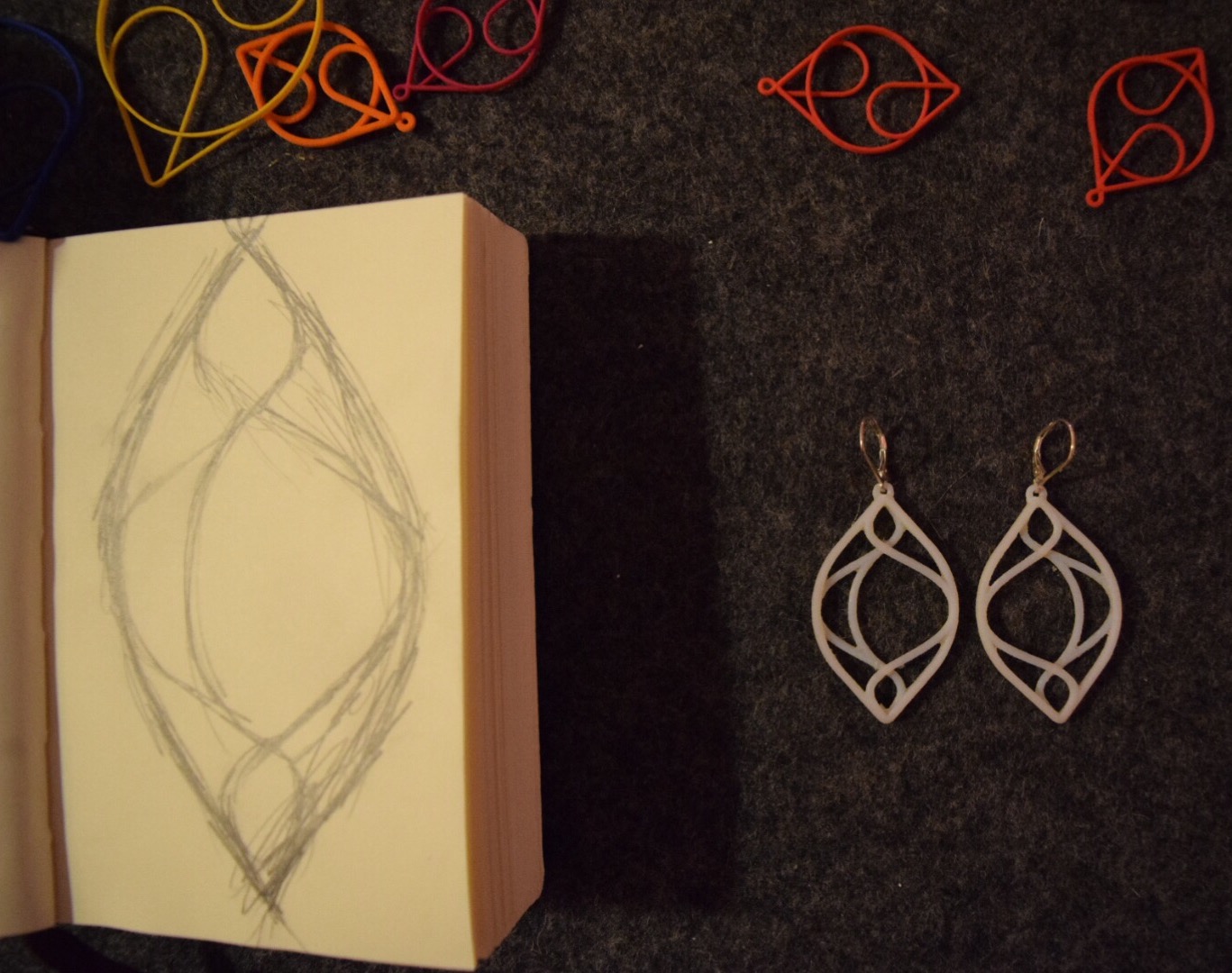

I keep my sketchbook nearby to capture design ideas. I am inspired by so many things I come into contact with during my day.

In addition to sketching, I will also work an idea through in my studio. Sitting at my bench, I solder together shapes using thin sterling silver wire and produce a simplified version of the design.

Prototyping the piece by hand gives me my first look into what the piece could be and helps me decide if I want to move on with the design. If I approve the design, it moves on to CAD file creation.

To Creation.

After I confirm the design, the design is recreated into a 3D CAD file format.

Many adjustments to the design are made during this period. The structural viability of the design is tested during this stage to make sure that the piece is wearable post-printing.

Once the file has been finalized, a prototype is printed. The prototype returns from the printer encased in a wax-like material which is carefully removed using an exacto-knife.

Each printed prototype is examined and changes that need to made are identified. Once these changes are incorporated, the file is sent off for a final printing that will be ready for sale!

The design is 3D printed using a very precise laser technique and then the earrings are polished and dyed. Over 12 engineers, designers, and quality control specialists handle your piece before returning it to me.

To You.

After the final prints are received, each piece is proofed to make sure that the quality is up to XLD standards.

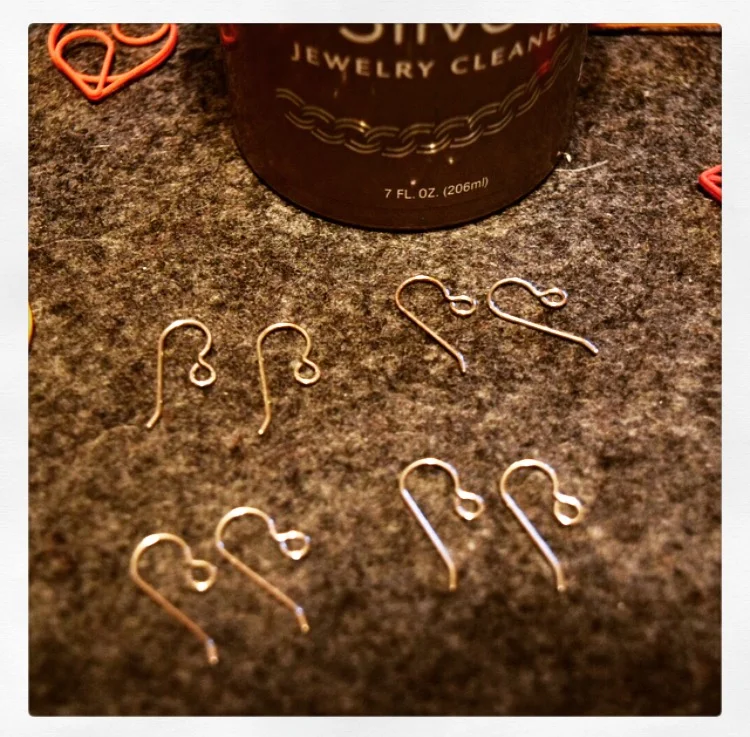

An antique finish is applied onto the sterling silver hooks using an old-school, natural method of immersing the hooks into the yolk of hardboiled eggs. The hooks are then cleaned and gently polished to bring back some of the silver sheen.

Once the hooks are attached, the earrings are boxed up with a short note from XLD.

Now they are ready for you. Enjoy ;)

Shop XLDs here.